5 Ways To Design The Ultimate Us Food Distribution Network Now

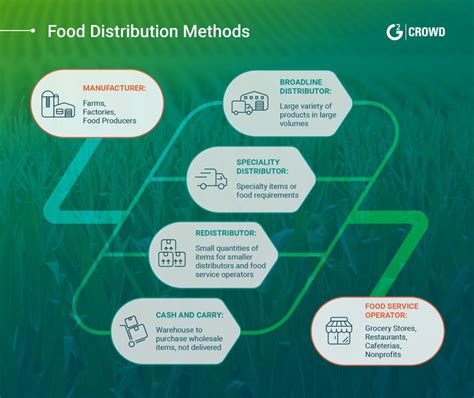

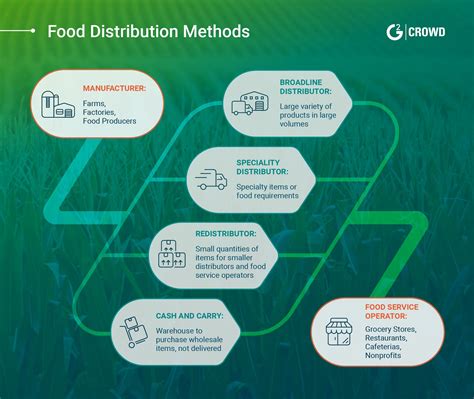

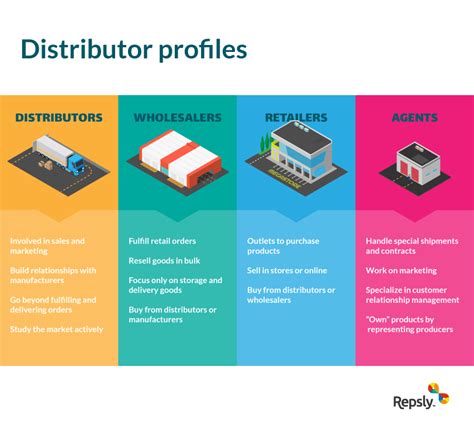

Introduction to Food Distribution Network Optimization

In today’s fast-paced and highly competitive food industry, building an efficient and well-designed food distribution network is crucial for businesses to thrive. With the right strategies in place, companies can streamline their operations, reduce costs, and enhance customer satisfaction. This blog post will explore five key ways to design the ultimate US food distribution network, ensuring a seamless and successful supply chain.

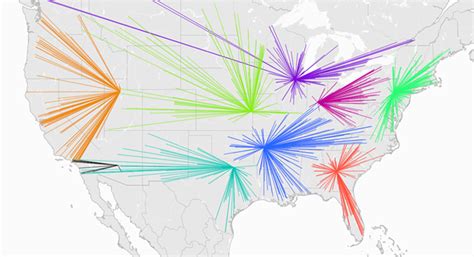

1. Strategic Location Selection

The first step in creating an effective food distribution network is careful location selection. Consider the following factors to make informed decisions:

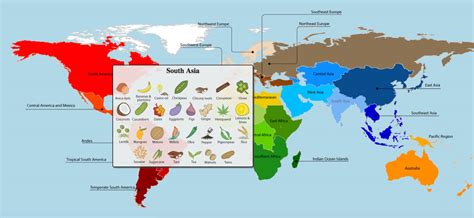

Market Analysis: Conduct a thorough analysis of the target market to identify areas with high demand for your products. Evaluate population density, purchasing power, and existing competition to determine the best locations for distribution centers.

Logistical Considerations: Assess the transportation infrastructure, including roads, railways, and ports, to ensure efficient movement of goods. Consider the proximity to major highways, intermodal facilities, and airports for faster and cost-effective distribution.

Supplier Proximity: Evaluate the proximity of your suppliers to potential distribution centers. Minimizing the distance between suppliers and distribution hubs can reduce transportation costs and lead times, improving overall efficiency.

Regulatory Compliance: Research and understand the local regulations and food safety standards in each region. Ensure that your distribution centers meet all necessary requirements to avoid legal issues and maintain product quality.

Customer Accessibility: Consider the accessibility of your distribution centers to your customer base. Strategically locate centers to minimize delivery times and ensure prompt order fulfillment.

2. Efficient Transportation Management

Optimizing transportation is vital for a successful food distribution network. Here’s how you can enhance your transportation management:

Route Optimization: Utilize advanced route optimization software to plan the most efficient delivery routes. Consider factors like traffic patterns, road conditions, and delivery schedules to minimize transit times and fuel costs.

Vehicle Selection: Choose the right vehicles for your fleet based on the nature of your products and delivery requirements. Consider factors such as capacity, fuel efficiency, and refrigeration needs to ensure timely and safe deliveries.

Last-Mile Delivery: Focus on improving last-mile delivery efficiency. Explore options like crowdsourcing, bike couriers, or electric vehicles for urban deliveries to reduce emissions and enhance sustainability.

Real-Time Tracking: Implement GPS tracking systems to monitor the movement of your vehicles and goods. This allows for better visibility, real-time updates, and the ability to optimize routes dynamically.

Collaborative Transport: Collaborate with other food businesses or logistics companies to share transportation resources. This can lead to cost savings, reduced environmental impact, and improved efficiency through consolidated shipments.

3. Advanced Inventory Management

Effective inventory management is crucial to prevent stockouts and minimize excess inventory. Here are some strategies to enhance your inventory management:

Just-in-Time (JIT) Inventory: Implement a JIT inventory system to ensure products are available when needed, reducing the need for excessive storage. This approach minimizes carrying costs and keeps your inventory fresh and in high demand.

Demand Forecasting: Utilize advanced analytics and historical data to forecast demand accurately. This enables you to maintain optimal stock levels, avoid overstocking, and ensure a consistent supply of products.

Real-Time Inventory Tracking: Implement a robust inventory management system that provides real-time visibility into stock levels, locations, and movement. This helps prevent stockouts, improves order fulfillment accuracy, and enables better decision-making.

Vendor Managed Inventory (VMI): Consider partnering with trusted suppliers who can manage your inventory levels. VMI allows suppliers to monitor your stock and restock as needed, reducing the administrative burden on your team.

Inventory Optimization Software: Invest in inventory optimization software that uses machine learning and AI to analyze data and make informed decisions. These tools can optimize reordering points, safety stock levels, and inventory placement, leading to improved efficiency.

4. Cold Chain Management

Maintaining the integrity of perishable food products throughout the supply chain is critical. Here’s how you can enhance your cold chain management:

Temperature Control: Ensure that your distribution centers and vehicles are equipped with state-of-the-art refrigeration systems to maintain the required temperature ranges. Regularly monitor and calibrate these systems to prevent temperature fluctuations.

Cold Chain Integrity: Implement a robust cold chain monitoring system to track and record temperature data throughout the distribution process. This ensures that products remain within the specified temperature ranges, preserving quality and safety.

Cold Storage Facilities: Invest in specialized cold storage facilities to store perishable goods at the right temperatures. These facilities should be well-maintained and equipped with backup power systems to prevent disruptions during power outages.

Temperature-Controlled Packaging: Use temperature-controlled packaging solutions, such as insulated containers or temperature-controlled pallets, to protect products during transportation. This helps maintain product quality and extends shelf life.

Cold Chain Training: Provide comprehensive training to your staff on cold chain management best practices. Educate them on the importance of temperature control, proper handling, and the impact of temperature deviations on product quality.

5. Sustainable Practices

Adopting sustainable practices not only benefits the environment but also enhances your brand reputation and customer loyalty. Here are some ways to incorporate sustainability into your food distribution network:

Reduce Food Waste: Implement strategies to minimize food waste at every stage of the supply chain. This includes optimizing ordering quantities, improving inventory management, and donating surplus food to food banks or charities.

Eco-Friendly Packaging: Choose sustainable and environmentally friendly packaging materials. Opt for recyclable or compostable options, reduce packaging waste, and consider reusable or refillable packaging systems.

Green Transportation: Transition to more sustainable transportation options, such as electric or hybrid vehicles. Explore alternative fuels and encourage eco-driving practices to reduce carbon emissions and fuel consumption.

Energy-Efficient Facilities: Invest in energy-efficient equipment and technologies for your distribution centers. This includes LED lighting, smart HVAC systems, and renewable energy sources like solar panels to reduce your carbon footprint.

Carbon Offset Programs: Consider participating in carbon offset programs to neutralize your carbon emissions. Support initiatives that promote reforestation, renewable energy projects, or other environmental conservation efforts.

Notes:

📍 Note: When selecting locations for distribution centers, consider the availability of skilled labor and the overall business environment in each region.

⚠️ Note: Ensure that your transportation management system integrates well with your inventory management and order fulfillment processes for seamless operations.

💡 Note: Consider implementing a reward system for employees who suggest innovative ideas to improve inventory management and reduce waste.

🌍 Note: Partnering with local farmers or producers can reduce transportation distances and support sustainable agriculture practices.

🌱 Note: Educate your customers about the environmental benefits of your sustainable practices to create a positive brand image and encourage loyalty.

Final Thoughts

Designing the ultimate US food distribution network requires a strategic approach that considers various factors, from location selection to sustainable practices. By implementing these five key strategies, businesses can optimize their operations, reduce costs, and provide an exceptional customer experience. Remember, a well-designed distribution network is the backbone of a successful food business, ensuring efficient supply chain management and long-term sustainability.

FAQ

How often should I review and optimize my distribution network strategy?

+

It is recommended to review and optimize your distribution network strategy annually or whenever significant changes occur in your business or market conditions. Regular reviews ensure that your network remains efficient and aligned with your goals.

What are some common challenges in implementing a sustainable food distribution network?

+

Challenges may include finding the right balance between cost-effectiveness and sustainability, dealing with limited infrastructure for sustainable transportation, and educating stakeholders about the importance of sustainable practices.

How can I measure the success of my distribution network improvements?

+

Key performance indicators (KPIs) such as delivery lead time, order fulfillment accuracy, customer satisfaction ratings, and cost per delivery can help measure the success of your distribution network improvements. Regularly track and analyze these metrics to identify areas for further optimization.