6 Tips To Design The Ultimate Thrust Vectoring Experience Now

Thrust vectoring is an exciting and complex technology that has revolutionized the aerospace and aviation industries. It allows for precise control and maneuverability of vehicles, opening up new possibilities for aircraft and spacecraft design. In this blog post, we will explore six essential tips to create an exceptional thrust vectoring experience, ensuring optimal performance and an unforgettable journey.

1. Understand the Fundamentals of Thrust Vectoring

Before diving into the design process, it is crucial to have a solid understanding of the fundamentals of thrust vectoring. Thrust vectoring involves manipulating the direction of the thrust produced by an engine, enabling the vehicle to change its orientation and trajectory. By controlling the angle and direction of the exhaust gases, engineers can achieve incredible levels of control and agility.

Here are some key concepts to grasp:

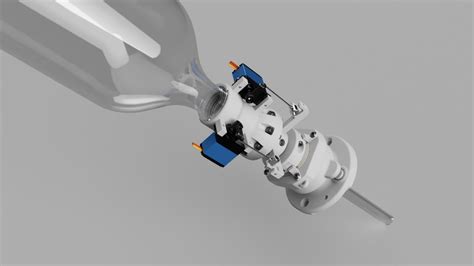

- Thrust Vectoring Methods: Explore different techniques such as gimbaled nozzles, fluidic thrust vectoring, and wing vectoring. Each method offers unique advantages and considerations.

- Engine Types: Understand the characteristics of various engine types, including turbojets, turbofans, and rocket engines, and how they influence thrust vectoring capabilities.

- Control Systems: Familiarize yourself with the control systems that govern thrust vectoring, including fly-by-wire and advanced computer algorithms.

Gaining a deep understanding of these fundamentals will provide a strong foundation for your design decisions.

2. Optimize Engine Placement and Configuration

The placement and configuration of engines play a critical role in achieving an exceptional thrust vectoring experience. Consider the following factors:

- Engine Location: Strategically position engines to maximize control authority and minimize structural interference. Optimal placement can vary depending on the vehicle's design and mission profile.

- Engine Arrangement: Determine the ideal arrangement of engines, whether it's single-engine, multi-engine, or distributed thrust systems. Consider the trade-offs between simplicity, redundancy, and control effectiveness.

- Thrust Vectoring Mechanisms: Choose the appropriate thrust vectoring mechanisms, such as gimbaled nozzles or fluidic control surfaces, based on the desired level of precision and responsiveness.

By carefully optimizing engine placement and configuration, you can enhance the overall performance and maneuverability of your vehicle.

3. Integrate Advanced Control Systems

To achieve precise and responsive thrust vectoring, integrating advanced control systems is essential. These systems utilize sophisticated algorithms and sensors to ensure smooth and accurate control of the vehicle's orientation.

- Fly-by-Wire Systems: Implement fly-by-wire technology, which replaces mechanical linkages with electronic signals, providing real-time control and improved safety.

- Sensor Fusion: Combine data from multiple sensors, such as accelerometers, gyroscopes, and GPS, to create a comprehensive understanding of the vehicle's position and orientation.

- Autopilot and Flight Control Software: Develop robust autopilot systems and flight control software to automate and optimize the thrust vectoring process, ensuring stability and efficiency.

Advanced control systems enable the vehicle to respond quickly and accurately to pilot inputs, making the thrust vectoring experience seamless and intuitive.

4. Consider Structural Integrity and Aerodynamics

Thrust vectoring can place significant demands on the vehicle's structure and aerodynamics. It is crucial to ensure that the design can withstand the forces generated during maneuverability.

- Structural Analysis: Conduct thorough structural analysis to identify potential stress points and ensure the vehicle can handle the loads imposed by thrust vectoring.

- Aerodynamic Optimization: Optimize the vehicle's shape and surface features to minimize drag and maximize lift, especially when performing high-angle-of-attack maneuvers.

- Materials Selection: Choose appropriate materials that offer a balance between strength, weight, and thermal resistance, considering the specific requirements of thrust vectoring operations.

By paying close attention to structural integrity and aerodynamics, you can create a robust and efficient design that performs exceptionally well during thrust vectoring maneuvers.

5. Enhance Pilot Experience and Ergonomics

The thrust vectoring experience is not just about the technology; it's also about the pilot's comfort and control. Focus on enhancing the pilot's experience and ergonomics to make the most of this advanced technology.

- Cockpit Design: Create an intuitive and ergonomic cockpit layout, ensuring easy access to critical controls and displays. Consider the pilot's posture and comfort during various flight modes.

- Control Interface: Develop an intuitive control interface that provides clear feedback and allows for precise input. Implement force feedback systems to enhance the pilot's sense of control.

- Training and Simulation: Provide comprehensive training programs and realistic simulations to familiarize pilots with the unique characteristics of thrust vectoring, ensuring they can make the most of its capabilities.

By prioritizing the pilot's experience, you can unlock the full potential of thrust vectoring and create an exhilarating and efficient flight experience.

6. Embrace Innovation and Testing

Thrust vectoring is an evolving field, and staying at the forefront of innovation is crucial. Embrace new technologies, materials, and design concepts to continuously improve the thrust vectoring experience.

- Research and Development: Invest in research and development to explore cutting-edge technologies, such as advanced materials, artificial intelligence, and virtual reality, that can enhance thrust vectoring capabilities.

- Testing and Validation: Conduct rigorous testing and validation procedures to ensure the safety and reliability of your design. Simulate various scenarios and gather data to refine and optimize the thrust vectoring system.

- Collaborative Efforts: Foster collaboration with experts and organizations in the field to exchange knowledge and best practices. Participate in industry events and conferences to stay updated on the latest advancements.

By embracing innovation and testing, you can push the boundaries of what is possible with thrust vectoring and create truly groundbreaking experiences.

Conclusion

Designing the ultimate thrust vectoring experience requires a deep understanding of the technology, careful consideration of engine placement and control systems, and a focus on structural integrity and pilot ergonomics. By following these six tips, you can create a vehicle that delivers exceptional performance, agility, and an unforgettable flight experience. Embrace the challenges and opportunities that thrust vectoring presents, and unlock the full potential of this remarkable technology.

What are some real-world applications of thrust vectoring technology?

+

Thrust vectoring has been utilized in various fields, including military aircraft, spacecraft, and even high-performance automobiles. In military aviation, it enables fighter jets to perform aggressive maneuvers and achieve superior agility. In space exploration, thrust vectoring is crucial for precise control during orbital maneuvers and landing on other celestial bodies. Additionally, some high-performance cars employ thrust vectoring systems to enhance cornering and stability.

Are there any safety considerations when implementing thrust vectoring systems?

+

Safety is a critical aspect of thrust vectoring design. Engineers must ensure that the system can handle extreme forces and maintain structural integrity. Additionally, robust control systems and fail-safe mechanisms are essential to prevent unintended movements or loss of control. Regular maintenance and thorough testing are also necessary to identify and address potential issues.

How does thrust vectoring impact fuel efficiency and range?

+

Thrust vectoring can have both positive and negative impacts on fuel efficiency and range. On one hand, the ability to precisely control the direction of thrust can reduce drag and improve overall efficiency. However, the additional mechanisms and control systems required for thrust vectoring may add weight and complexity, potentially affecting fuel consumption. Careful design and optimization are necessary to strike a balance between performance and fuel efficiency.