Design The Ultimate Chain Gun In 5 Easy Steps Today

Unleash your inner weapons designer and embark on a journey to create the ultimate chain gun! In this comprehensive guide, we'll break down the process into five simple steps, ensuring you craft a formidable firearm that will leave your opponents in awe. Whether you're a seasoned enthusiast or a novice with a passion for weaponry, this tutorial will provide you with the knowledge and inspiration to design a chain gun that embodies power, precision, and innovation. Get ready to unleash your creativity and join us on this exciting adventure!

Step 1: Understanding the Chain Gun Mechanism

Before diving into the design process, it's crucial to grasp the fundamentals of the chain gun mechanism. Chain guns, also known as Gatling guns, are rapid-fire weapons that utilize a rotating barrel system. This unique design allows for continuous firing without the need for manual reloading. The key components of a chain gun include the barrels, ammunition feed system, and a power source to drive the rotation.

Here's a breakdown of the essential elements:

- Barrels: The barrels are the heart of the chain gun, responsible for firing the ammunition. Multiple barrels arranged in a circular pattern provide continuous fire. The number of barrels and their arrangement can vary, impacting the gun's rate of fire and overall performance.

- Ammunition Feed System: This system ensures a steady supply of ammunition to the barrels. It can be designed to feed bullets from a belt or a magazine, depending on the desired capacity and reload speed.

- Power Source: Chain guns require a power source to rotate the barrels and feed the ammunition. This can be an electric motor, gas turbine, or even a manual crank for simpler designs. The choice of power source influences the gun's weight, portability, and rate of fire.

Understanding these core components will serve as a solid foundation for your chain gun design. Now, let's explore the first step in bringing your creation to life.

Step 2: Define Your Chain Gun's Purpose

Every weapon has a specific purpose, and your chain gun is no exception. Defining the intended use of your gun will guide your design choices and ensure it meets the desired requirements. Consider the following factors when defining your chain gun's purpose:

- Application: Will your chain gun be used for military purposes, law enforcement, recreational shooting, or a combination of these? Understanding the intended application will help determine the necessary features and performance characteristics.

- Range and Accuracy: Decide on the effective range and accuracy requirements for your gun. Do you prioritize long-range precision or close-quarters firepower? This decision will influence the barrel length, caliber, and optics.

- Rate of Fire: Chain guns are known for their high rate of fire. Determine the desired firing speed, considering factors like ammunition capacity, reload time, and the intended target engagement scenarios.

- Portability and Maneuverability: Think about the environments and situations in which your chain gun will be used. Is portability a priority, or do you prioritize stability and accuracy over mobility? This will impact the overall size, weight, and handling characteristics of your design.

By clearly defining your chain gun's purpose, you can make informed design decisions and create a weapon tailored to your specific needs. Now, let's move on to the next step and explore the critical components that will bring your vision to life.

Step 3: Choose Your Components

With a clear understanding of your chain gun's purpose, it's time to select the components that will make up your design. Here's a breakdown of the key components you'll need to consider:

- Barrels: Select the number of barrels and their arrangement based on your desired rate of fire and ammunition capacity. Common barrel configurations include 3, 6, or 8 barrels, but you can experiment with different arrangements to achieve your unique design goals.

- Ammunition Feed System: Choose between a belt-fed or magazine-fed system. Belt-fed systems offer higher ammunition capacity and continuous fire, while magazine-fed systems provide easier reloading and better portability. Consider the trade-offs and select the feed system that aligns with your design objectives.

- Power Source: Decide on the power source that best suits your chain gun's purpose. Electric motors offer precision control and low maintenance, while gas turbines provide higher power output and mobility. Evaluate the pros and cons of each option and select the one that aligns with your design vision.

- Optics and Sights: Choose the appropriate optics and sights to enhance your chain gun's accuracy. This can include scopes, red dot sights, or holographic sights, depending on your intended range and application. Select the optics that provide the best balance between precision and ease of use.

- Grip and Stock: Select a grip and stock design that ensures comfortable handling and control. Consider factors like weight distribution, ergonomics, and the intended shooting position. A well-designed grip and stock will improve your chain gun's maneuverability and accuracy.

As you select your components, keep in mind the overall balance and weight distribution of your design. Aim for a harmonious blend of performance, portability, and user-friendliness. Now, let's move on to the next step and bring your chain gun to life with precision engineering.

Step 4: Engineering and Assembly

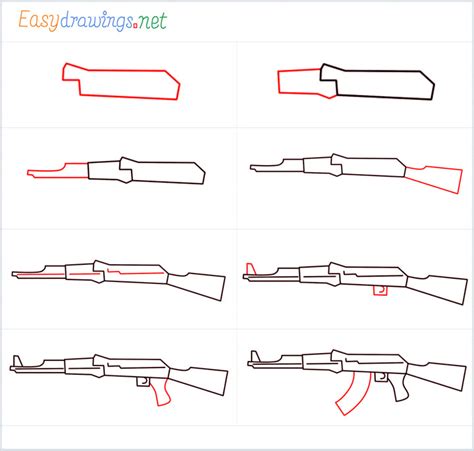

With your components selected, it's time to put your engineering skills to the test and assemble your chain gun. Here's a step-by-step guide to help you through the process:

- Frame and Mounting: Start by constructing the frame that will house your chain gun's components. Ensure it provides a sturdy foundation and allows for easy mounting of the barrels, feed system, and power source. Consider using lightweight materials to reduce overall weight without compromising structural integrity.

- Barrel Assembly: Install the selected number of barrels onto the frame, ensuring proper alignment and balance. Pay attention to the spacing between barrels to optimize gas flow and minimize recoil. Test fire the barrels individually to ensure they function correctly before proceeding.

- Ammunition Feed System Integration: Integrate the chosen feed system into the frame, ensuring a smooth and reliable ammunition flow. Properly align the feed system with the barrels to prevent jams and ensure consistent feeding. Test the feed system to confirm it delivers ammunition smoothly and efficiently.

- Power Source Installation: Mount the selected power source onto the frame, ensuring it is securely attached and easily accessible for maintenance. Connect the power source to the barrel rotation mechanism and test the system to verify smooth and controlled rotation.

- Optics and Sights Installation: Mount the chosen optics and sights onto the chain gun, considering the intended shooting position and range. Ensure they are properly aligned and provide a clear and accurate sight picture. Test the optics and sights to confirm their precision and ease of use.

- Final Assembly and Testing: Bring all the components together, ensuring a secure and seamless fit. Conduct a thorough inspection to identify any potential issues or misalignments. Test fire the chain gun to verify its performance, accuracy, and overall functionality. Make any necessary adjustments to optimize its performance.

During the engineering and assembly process, pay close attention to detail and precision. Ensure all components are properly aligned and secured to prevent malfunctions and ensure optimal performance. Now, let's move on to the final step and explore the importance of safety and maintenance.

Step 5: Safety and Maintenance

Creating a powerful chain gun is an exciting endeavor, but it's crucial to prioritize safety and proper maintenance to ensure its reliable performance and longevity. Here are some key considerations to keep in mind:

- Safety Protocols: Develop a comprehensive set of safety protocols for handling and operating your chain gun. This includes proper training, ammunition handling procedures, and guidelines for safe storage and transportation. Ensure all users are well-versed in these protocols to prevent accidents and ensure responsible use.

- Regular Maintenance: Establish a maintenance schedule to keep your chain gun in top condition. Regularly inspect and clean all components, paying close attention to moving parts, gas seals, and ammunition feed systems. Lubricate as necessary and replace any worn-out or damaged parts to maintain optimal performance.

- Ammunition Compatibility: Ensure that the ammunition you use is compatible with your chain gun's caliber and feed system. Using the wrong ammunition can lead to malfunctions, jams, or even catastrophic failures. Always refer to the manufacturer's guidelines and conduct thorough testing to confirm compatibility.

- Storage and Transportation: Develop a secure storage solution for your chain gun when not in use. Ensure it is properly locked and inaccessible to unauthorized individuals. When transporting your chain gun, use a sturdy case or container to protect it from damage and prevent accidental discharge.

By implementing robust safety measures and a well-planned maintenance routine, you can ensure the safe and reliable operation of your chain gun. Now, let's conclude our journey and reflect on the process of designing the ultimate chain gun.

Final Thoughts

Congratulations! You've successfully designed and built your very own chain gun. Throughout this guide, we've explored the key steps to creating a formidable firearm, from understanding the chain gun mechanism to prioritizing safety and maintenance. By following these steps and applying your creativity and engineering skills, you've crafted a weapon that embodies power, precision, and innovation.

As you continue to refine and enhance your chain gun, remember that the process of designing and building weaponry is an ongoing journey. Stay curious, explore new technologies, and embrace continuous learning. With each iteration, your chain gun will become more refined, more reliable, and more tailored to your specific needs.

So, embrace the spirit of innovation, push the boundaries of what's possible, and continue to unlock the full potential of your ultimate chain gun. Happy designing and shooting!

What are the key benefits of a chain gun over traditional firearms?

+

Chain guns offer a higher rate of fire and continuous firing without manual reloading, making them ideal for scenarios requiring sustained firepower. They also provide better accuracy and stability due to their multi-barrel design.

Can I customize the ammunition capacity of my chain gun?

+

Absolutely! The ammunition capacity of your chain gun can be customized by choosing the appropriate feed system and ammunition type. Belt-fed systems offer higher capacity, while magazine-fed systems provide easier reloading.

What are some common challenges when designing a chain gun?

+

Common challenges include managing recoil, ensuring smooth ammunition feeding, and maintaining a balanced weight distribution. Proper engineering and attention to detail are crucial to overcoming these challenges.

How can I improve the accuracy of my chain gun?

+

To improve accuracy, consider using higher-quality ammunition, optimizing barrel length and caliber, and investing in advanced optics and sights. Regular practice and training will also enhance your accuracy over time.

Are there any legal considerations when building a chain gun?

+

Yes, it’s important to be aware of local laws and regulations regarding the ownership and use of firearms, including chain guns. Always ensure you are in compliance with relevant laws and obtain any necessary permits or licenses.