Expert Guide: 10 Ways To Create Mach Power

Whether you're a seasoned machinist or just starting out, understanding the concept of mach power is crucial for achieving precision and efficiency in your projects. In this comprehensive guide, we will delve into the top 10 techniques to harness mach power and elevate your machining game. By implementing these strategies, you'll be able to create exceptional workpieces with accuracy and ease.

1. Master the Basics of Machining

Before diving into advanced techniques, it's essential to have a solid foundation in machining principles. Understand the fundamentals of cutting tools, workholding, and machine setup. Familiarize yourself with different machining processes, such as turning, milling, and drilling, and their respective applications.

2. Choose the Right Cutting Tools

Selecting the appropriate cutting tools is crucial for optimizing mach power. Consider factors such as the material you're working with, the desired surface finish, and the cutting speed and feed rates. Invest in high-quality cutting tools that are suitable for your specific machining needs. Regularly inspect and maintain your tools to ensure optimal performance.

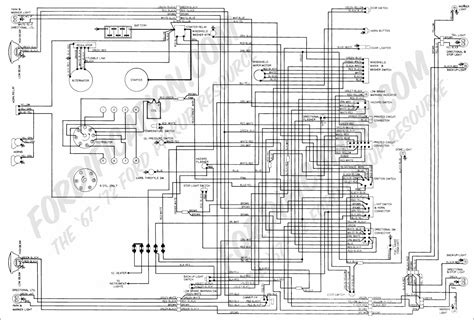

3. Optimize Machine Setup

A well-configured machine is key to unlocking mach power. Ensure your machine is properly aligned and calibrated. Adjust the spindle speed, feed rate, and depth of cut based on the material and tool specifications. Pay attention to workpiece clamping and ensure a secure and stable setup to minimize vibrations and achieve precise cuts.

4. Utilize CNC Technology

Computer Numerical Control (CNC) machines offer unparalleled precision and control. Invest in CNC machining if you haven't already. With CNC technology, you can program and automate your machining processes, reducing human error and increasing productivity. Learn the basics of CNC programming and utilize CAD/CAM software to design and generate toolpaths for complex parts.

5. Master Toolpath Programming

Efficient toolpath programming is essential for maximizing mach power. Understand the different types of toolpaths, such as contouring, pocketing, and drilling, and their respective applications. Optimize your toolpaths by considering factors like tool engagement, chip load, and stepover. Experiment with different strategies and techniques to find the most suitable toolpath for your specific machining requirements.

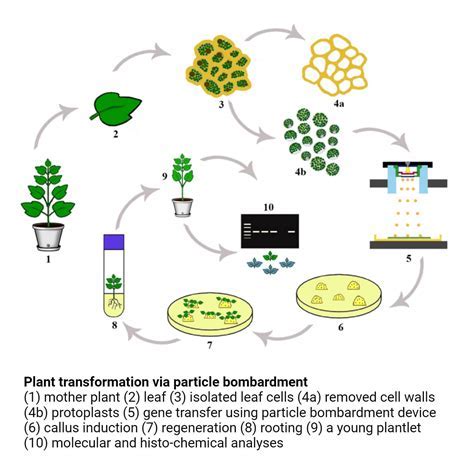

6. Implement Advanced Machining Techniques

Explore advanced machining techniques to enhance your mach power. Techniques such as high-speed machining, trochoidal milling, and peel milling can significantly improve material removal rates and surface finish. Research and experiment with these techniques to find the ones that best suit your machining goals and the materials you work with.

7. Optimize Cutting Parameters

Fine-tuning your cutting parameters is crucial for achieving optimal mach power. Experiment with different cutting speeds, feed rates, and depth of cut to find the sweet spot for your specific machining setup. Consider the material's hardness, toughness, and thermal properties when determining the optimal cutting parameters. Consult cutting data charts and manufacturer recommendations for guidance.

8. Utilize Coolant Effectively

Proper coolant application is essential for maintaining mach power and prolonging tool life. Select the appropriate coolant type and delivery method based on the material and machining process. Ensure a consistent and controlled flow of coolant to the cutting zone to prevent excessive heat buildup and minimize tool wear. Regularly maintain and clean your coolant system to ensure optimal performance.

9. Implement Quality Control Measures

Quality control is vital to ensure consistent mach power and achieve accurate results. Set up a comprehensive quality control system that includes regular inspections and measurements. Utilize precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM) to verify the dimensions and tolerances of your workpieces. Implement statistical process control (SPC) techniques to monitor and control your machining processes.

10. Continuous Learning and Improvement

The world of machining is constantly evolving, and staying up-to-date with the latest advancements is crucial. Invest time in continuous learning and professional development. Attend industry conferences, workshops, and training sessions to expand your knowledge and skills. Stay connected with fellow machinists and industry experts to exchange ideas and best practices. Embrace a culture of continuous improvement to stay at the forefront of machining technology.

Conclusion

By implementing these 10 ways to create mach power, you'll be well on your way to becoming a machining expert. Remember, mastering mach power is a journey that requires dedication, practice, and a willingness to learn. With the right techniques, tools, and mindset, you can achieve exceptional results and elevate your machining capabilities to new heights.

What is mach power in machining?

+Mach power refers to the ability to achieve precise and efficient machining results. It encompasses various factors such as cutting tool selection, machine setup, toolpath programming, and optimization of cutting parameters.

Why is mastering mach power important?

+Mastering mach power allows machinists to produce high-quality workpieces with accuracy and efficiency. It helps reduce waste, minimize tool wear, and improve overall productivity in the machining process.

How can I improve my machining skills to achieve mach power?

+To improve your machining skills and achieve mach power, focus on mastering the basics, investing in high-quality tools, optimizing machine setup, and exploring advanced machining techniques. Continuous learning and staying updated with industry advancements are also crucial.

What are some common challenges in achieving mach power?

+Common challenges in achieving mach power include selecting the right cutting tools, optimizing cutting parameters, and managing coolant effectively. Additionally, ensuring proper workholding and maintaining a stable machine setup are crucial for achieving optimal results.

How can I stay updated with the latest machining advancements?

+To stay updated with the latest machining advancements, attend industry conferences, subscribe to relevant machining publications, and join online communities and forums where machinists share their knowledge and experiences. Continuous learning and networking with industry experts are key.