How Crayons Are Made

The Fascinating Process of Crayon Creation

Crayons are an iconic art supply, beloved by children and artists alike. But have you ever wondered how these colorful sticks are made? The journey from raw materials to the vibrant crayons we know and love is an intriguing one, involving a blend of science and craftsmanship. Let’s explore the step-by-step process of crayon manufacturing.

Step 1: Sourcing Raw Materials

The foundation of any crayon is its wax base, typically a blend of paraffin wax and beeswax. These natural materials are carefully selected and sourced to ensure the highest quality. Paraffin wax, derived from petroleum, provides the crayon with its smooth texture and bright colors, while beeswax adds a touch of natural shine and improves its durability.

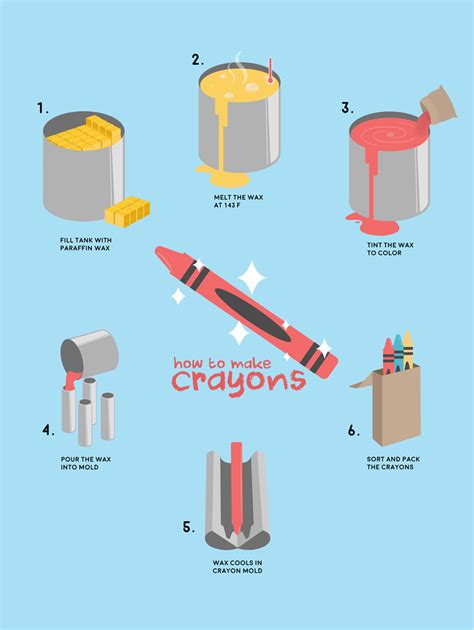

Step 2: Wax Melting and Coloring

Once the waxes are acquired, they are melted down in large vats. This melting process is crucial as it allows for the addition of pigments, the colorful components that give crayons their distinctive hues. These pigments are carefully measured and blended into the molten wax, creating a vibrant mixture. The wax is then cooled to a specific temperature, ensuring that the pigments are evenly distributed throughout the wax.

Step 3: Pouring and Shaping

The next step involves pouring the colored wax into molds. These molds are designed to shape the wax into the iconic crayon form we all recognize. The wax is carefully poured into the molds, which are then cooled to solidify the crayons. This process is precise, as it determines the final shape and size of the crayons.

Step 4: Labeling and Packaging

After the crayons have cooled and solidified, they are carefully removed from the molds. Each crayon is then labeled with its corresponding color, ensuring easy identification for artists. The crayons are then packaged into boxes, often with a variety of colors to cater to different artistic needs.

Step 5: Quality Control

Before the crayons are ready for distribution, they undergo rigorous quality control checks. This ensures that each crayon meets the highest standards of color, consistency, and durability. Any crayons that fail to meet these standards are removed from the batch, ensuring that only the best crayons reach consumers.

A Note on Crayon Safety

Crayons are generally considered safe for children, as they are non-toxic and pose no significant health risks. However, it’s important to supervise young artists to prevent any accidental ingestion, as crayons are not meant to be eaten. Additionally, crayons should be stored in a cool, dry place to maintain their quality and prevent melting.

Conclusion

The process of crayon manufacturing is a delicate balance of art and science. From the careful selection of raw materials to the precise shaping and labeling, every step contributes to the creation of these beloved art tools. So, the next time you reach for a crayon, take a moment to appreciate the intricate journey it took to get into your hands.

How are crayons made without beeswax?

+

While beeswax is commonly used in crayon production, some manufacturers opt for a synthetic alternative. This synthetic wax can mimic the properties of beeswax, providing a similar shine and durability. This approach caters to those with allergies or dietary restrictions, ensuring that everyone can enjoy crayons.

Can I make my own crayons at home?

+

Absolutely! Homemade crayons can be a fun and creative project. You’ll need paraffin wax, pigment powder, and a mold. Melt the wax, add the pigment, and pour into the mold. Let it cool, and you have your very own crayons! Just remember to exercise caution when working with melted wax.

What is the history of crayons?

+

Crayons have a rich history dating back to the 19th century. The first crayons were created by Edwin Binney and C. Harold Smith, who aimed to provide a safe and affordable art medium for children. Over time, crayons evolved, with new colors and improved formulas, becoming an essential tool for artists and a beloved toy for kids.