Round Steel Bracing Bars

Understanding the Importance of Round Steel Bracing Bars

Round steel bracing bars, often referred to as RSBs, are essential components in construction and engineering projects. These bars play a crucial role in providing structural support and enhancing the stability of various structures, ensuring their safety and longevity. In this blog post, we will delve into the world of round steel bracing bars, exploring their applications, benefits, and best practices for installation. Whether you’re a construction professional or simply curious about the inner workings of structural engineering, this guide will provide valuable insights into the significance of RSBs.

Applications of Round Steel Bracing Bars

Round steel bracing bars find extensive use in a wide range of construction projects, offering versatile solutions for different structural needs. Here are some key applications where RSBs prove invaluable:

- Residential Construction: RSBs are commonly employed in residential buildings, providing additional support to walls, especially in areas prone to high winds or seismic activity. They help prevent structural damage and ensure the safety of occupants.

- Commercial Buildings: In commercial construction, round steel bracing bars are used to reinforce concrete structures, steel frames, and load-bearing walls. They enhance the overall stability of the building, allowing for larger open spaces and reducing the need for internal support columns.

- Bridge Construction: Bridges, being critical infrastructure, require robust support systems. RSBs are often utilized to brace bridge supports, ensuring they can withstand heavy loads and environmental stresses, such as strong winds or earthquakes.

- Industrial Facilities: Industrial facilities, including factories and warehouses, often house heavy machinery and equipment. Round steel bracing bars are essential in these settings, providing the necessary structural integrity to support the weight and vibrations generated by industrial processes.

- Retaining Walls: Retaining walls, designed to hold back soil or water, require strong and reliable support systems. RSBs are an ideal choice for reinforcing these walls, preventing soil erosion and ensuring the stability of the structure.

Benefits of Using Round Steel Bracing Bars

The advantages of incorporating round steel bracing bars into construction projects are significant. Here’s why RSBs are a preferred choice for engineers and contractors:

- Enhanced Structural Stability: RSBs provide exceptional structural support, improving the overall stability of buildings and other structures. By distributing loads evenly and resisting lateral forces, they help prevent deformation and collapse, ensuring the safety of occupants and users.

- Seismic Resistance: In regions prone to earthquakes, round steel bracing bars are vital for seismic resistance. They absorb and dissipate the energy generated by seismic events, reducing the risk of structural damage and protecting lives.

- Wind Resistance: High winds can exert significant lateral forces on buildings, leading to potential structural failures. RSBs effectively resist these forces, preventing wind-induced damage and ensuring the longevity of the structure.

- Cost-Effectiveness: While RSBs offer exceptional performance, they are also cost-effective compared to other structural support systems. Their durability and ease of installation make them a practical choice for a wide range of construction projects.

- Versatility: Round steel bracing bars can be customized to fit various structural requirements. They are available in different sizes, grades, and finishes, allowing engineers to select the most suitable option for each specific application.

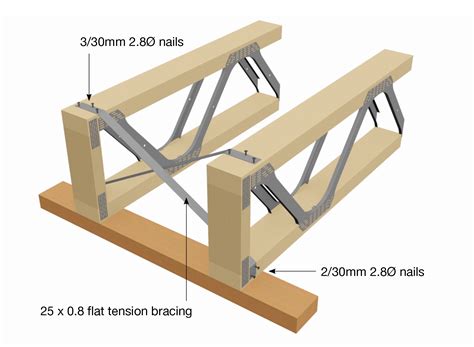

Best Practices for Installing Round Steel Bracing Bars

To ensure the effectiveness and longevity of round steel bracing bars, proper installation is crucial. Here are some best practices to follow:

- Site Preparation: Before installation, ensure the site is clean and free from debris. Properly level the surface to create a stable base for the RSBs.

- Measurement and Planning: Accurate measurements are essential. Plan the layout of the bracing bars, considering the structural requirements and load distribution.

- Connection Points: Identify and prepare the connection points where the RSBs will be attached to the structure. Ensure these points are strong and capable of withstanding the forces exerted by the bracing bars.

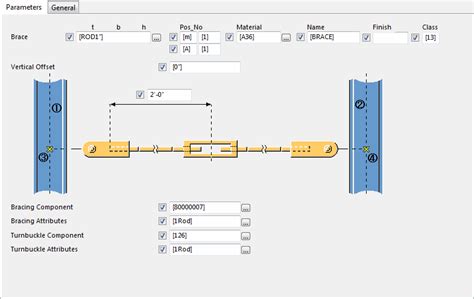

- Welding and Bolting: Round steel bracing bars can be installed using welding or bolting techniques. Welding provides a strong and permanent connection, while bolting allows for easier adjustments and maintenance.

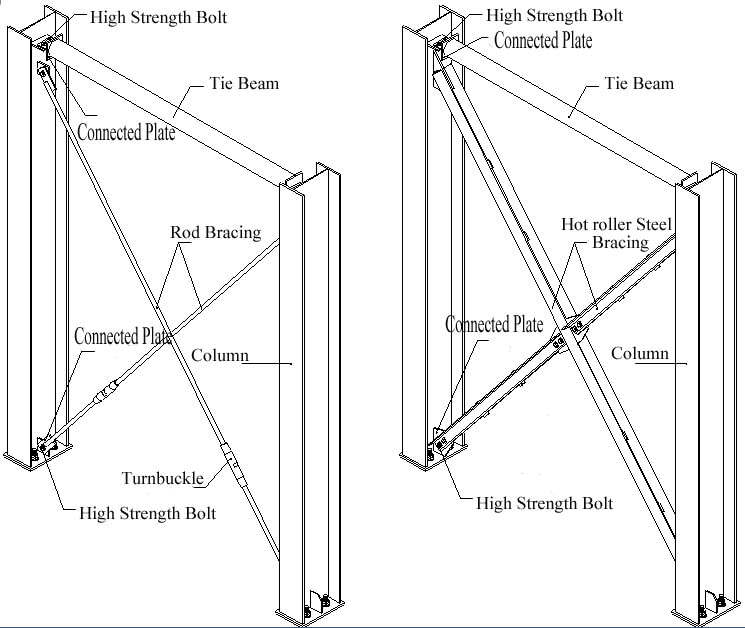

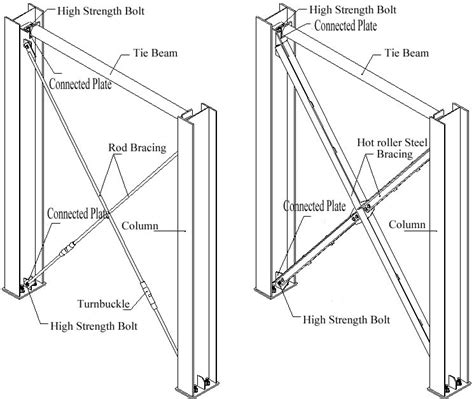

- Bracing Patterns: Determine the most suitable bracing pattern based on the structural design. Common patterns include X-bracing, K-bracing, and V-bracing, each offering unique advantages for different applications.

- Quality Control: Conduct thorough quality control checks during and after installation. Inspect the connections, ensure proper alignment, and verify that the bracing bars are securely fastened.

- Regular Maintenance: Implement a regular maintenance schedule to inspect and maintain the RSBs. Check for any signs of corrosion, damage, or loosening of connections, and address any issues promptly.

Choosing the Right Round Steel Bracing Bars

With a wide variety of RSB options available, selecting the most suitable bracing bars for your project can be a daunting task. Here are some factors to consider when making your choice:

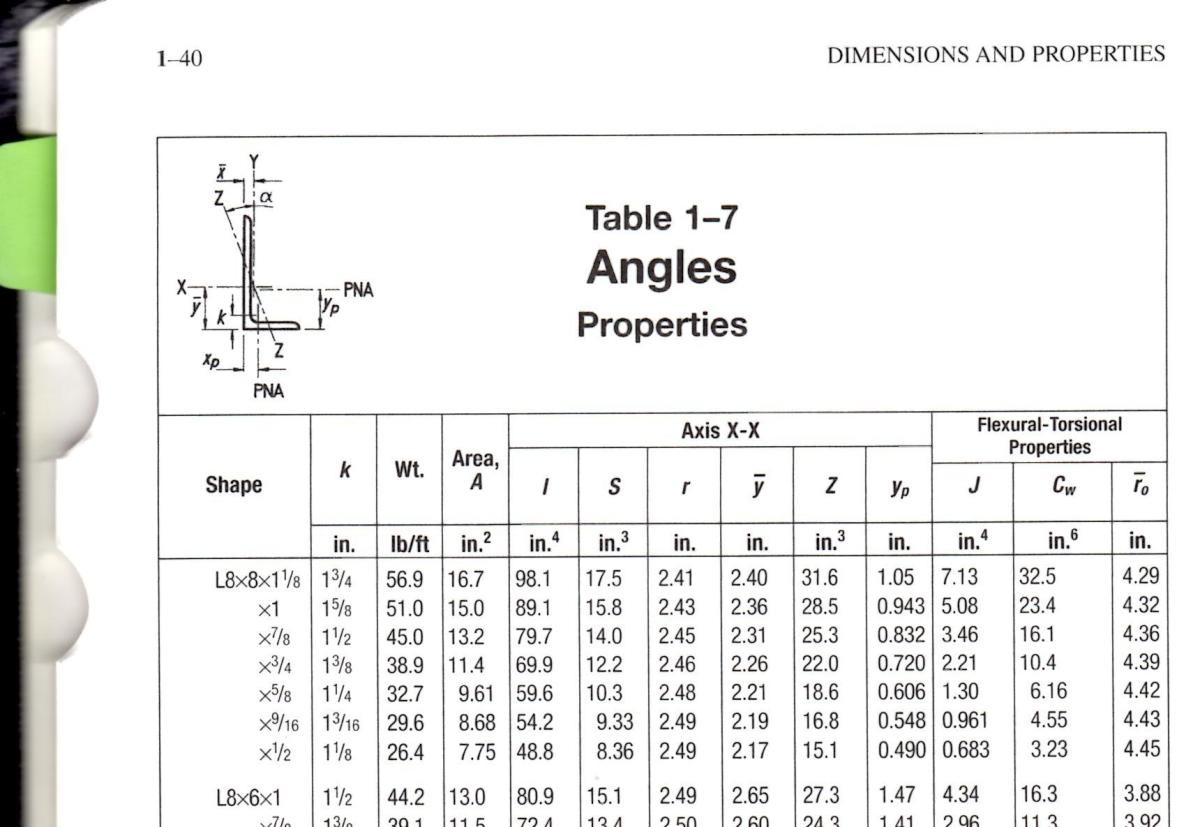

- Grade and Strength: Different grades of steel offer varying levels of strength and durability. Choose a grade that aligns with the structural requirements and expected loads of your project.

- Size and Thickness: The size and thickness of the bracing bars should be determined based on the dimensions and weight of the structure they will support. Consult with structural engineers to ensure the correct sizing.

- Corrosion Resistance: Consider the environmental conditions of the project site. If the structure is exposed to moisture, salt, or corrosive substances, opt for bracing bars with corrosion-resistant coatings or finishes.

- Certification and Standards: Ensure that the round steel bracing bars you choose meet industry standards and are certified for their intended use. This guarantees the quality and performance of the product.

Round Steel Bracing Bars vs. Other Support Systems

While round steel bracing bars are a popular choice, there are alternative support systems available. Here’s a comparison to help you understand the unique advantages of RSBs:

| Support System | Pros | Cons |

|---|---|---|

| Round Steel Bracing Bars |

|

|

| Strut Channels |

|

|

| Steel Columns |

|

|

Maintenance and Longevity

To maximize the lifespan and performance of round steel bracing bars, regular maintenance is essential. Here are some key maintenance practices:

- Inspection: Conduct regular inspections to identify any signs of wear, corrosion, or damage. Address any issues promptly to prevent further deterioration.

- Cleaning: Keep the bracing bars clean and free from debris. Remove any dirt, grease, or corrosion-causing substances to maintain their structural integrity.

- Coating and Painting: Apply protective coatings or paint to the RSBs, especially in corrosive environments. This helps prevent rust and extends their service life.

- Tightening Connections: Periodically check and tighten all connections to ensure they remain secure. Loose connections can compromise the structural stability of the bracing system.

- Professional Maintenance: Engage qualified professionals for routine maintenance and repairs. They can provide expert advice and ensure the bracing bars are maintained to the highest standards.

🛠️ Note: It's crucial to consult with structural engineers and follow local building codes and regulations when installing and maintaining round steel bracing bars.

Conclusion

Round steel bracing bars are indispensable components in construction and engineering, offering unparalleled structural support and stability. From residential buildings to industrial facilities, RSBs play a vital role in ensuring the safety and longevity of various structures. By understanding their applications, benefits, and installation best practices, professionals can make informed decisions to enhance the overall performance and durability of their projects. With proper selection, installation, and maintenance, round steel bracing bars will continue to be a reliable and trusted solution for years to come.