What Does Spark Arrestor Do

A spark arrestor is an essential component in various industrial and agricultural machinery, especially those that involve combustion processes. Its primary function is to prevent the escape of burning embers, sparks, or hot particles, which can pose significant fire hazards and environmental risks. This blog post will delve into the workings of spark arrestors, their importance, and their applications across different industries.

Understanding Spark Arrestors

Spark arrestors are devices designed to trap and contain burning materials, typically produced during the combustion process. They are an integral part of exhaust systems, ensuring that any potential fire hazards are mitigated before they can cause harm.

How Do Spark Arrestors Work?

The basic principle behind spark arrestors is simple: they use a series of filters or screens to capture and hold back any burning particles. These screens are made from materials that can withstand high temperatures, such as stainless steel or ceramic. The exhaust gases pass through these screens, allowing the clean air to escape while trapping the sparks or embers.

Some spark arrestors also utilize a water-based system, where the exhaust gases are passed through a water bath, effectively extinguishing any sparks or hot particles.

The Importance of Spark Arrestors

The significance of spark arrestors cannot be overstated, especially in industries where combustion processes are prevalent. Here are some key reasons why spark arrestors are crucial:

- Fire Prevention: The primary function of spark arrestors is to prevent fires. In industries like forestry, agriculture, and construction, where machinery operates in dry or flammable environments, sparks from exhaust systems can easily ignite fires. Spark arrestors mitigate this risk, ensuring the safety of both the workers and the surrounding environment.

- Environmental Protection: Spark arrestors play a vital role in reducing air pollution. Burning embers and sparks can carry harmful pollutants, such as particulate matter and unburned hydrocarbons, which can have detrimental effects on air quality. By trapping these particles, spark arrestors help maintain cleaner air, benefiting both human health and the environment.

- Equipment Protection: Spark arrestors not only prevent external fires but also protect the machinery itself. Hot sparks and embers can damage the engine and other components, leading to costly repairs and downtime. By trapping these particles, spark arrestors extend the lifespan of the equipment and reduce maintenance costs.

Applications of Spark Arrestors

Spark arrestors find applications in a wide range of industries, including but not limited to:

- Forestry and Agriculture: Spark arrestors are commonly used in forestry equipment, such as chainsaws and harvesters, to prevent the spread of wildfires. In agriculture, they are employed in tractors, combines, and other machinery to reduce the risk of fires in fields and forests.

- Construction and Mining: Construction sites often involve the use of heavy machinery with combustion engines. Spark arrestors are essential in these industries to prevent fires caused by sparks from exhaust systems, especially in dry or dusty environments.

- Marine Engines: Boats and ships powered by diesel engines require spark arrestors to prevent the escape of sparks and hot particles. This is crucial for the safety of both the vessel and the surrounding marine environment.

- Power Generation: Spark arrestors are used in power plants and generators to control emissions and prevent fires. They ensure that the exhaust gases are properly filtered before being released into the atmosphere.

Types of Spark Arrestors

There are several types of spark arrestors, each designed for specific applications and industries. Here are some common types:

- Screen Spark Arrestors: These are the most common type, consisting of a series of screens or filters. The screens are made from materials like stainless steel or ceramic, and they capture and hold back sparks and embers.

- Water-Based Spark Arrestors: As the name suggests, these arrestors use water to extinguish sparks. The exhaust gases pass through a water bath, effectively cooling and extinguishing any hot particles.

- Multi-Stage Spark Arrestors: These arrestors combine multiple stages of filtration, often using a combination of screens and water-based systems. They provide an added layer of protection and are commonly used in high-risk applications.

- Catalytic Spark Arrestors: These arrestors use a catalytic process to convert harmful pollutants into less harmful substances. They are often used in conjunction with other spark arrestor types to further reduce emissions.

Maintenance and Cleaning

Regular maintenance and cleaning of spark arrestors are crucial to ensure their effectiveness. Over time, the screens or filters can become clogged with debris, reducing their efficiency. Here are some tips for maintaining spark arrestors:

- Inspect spark arrestors regularly for any signs of damage or wear. Replace them if necessary.

- Clean the screens or filters according to the manufacturer's instructions. This may involve removing and washing the screens or using specialized cleaning agents.

- Ensure that the spark arrestor is properly installed and secured. Loose connections can affect its performance.

- Keep the surrounding area clean and free from debris. This prevents the buildup of dirt and dust, which can hinder the arrestor's functionality.

Regulations and Standards

Spark arrestors are subject to various regulations and standards to ensure their effectiveness and safety. These regulations vary depending on the industry and region. It is essential to comply with the relevant standards to avoid legal issues and ensure the safety of operations.

Conclusion

Spark arrestors are an essential component in industries where combustion processes are prevalent. They play a crucial role in preventing fires, protecting the environment, and ensuring the safety of workers and equipment. By understanding the different types of spark arrestors and their applications, industries can make informed decisions to mitigate fire risks and maintain a safe working environment.

What is the difference between a spark arrestor and a muffler?

+

A spark arrestor is designed specifically to trap and contain sparks and burning particles, while a muffler is primarily used to reduce the noise produced by the exhaust system. While some mufflers may have spark arrestor capabilities, they are not as effective as dedicated spark arrestors.

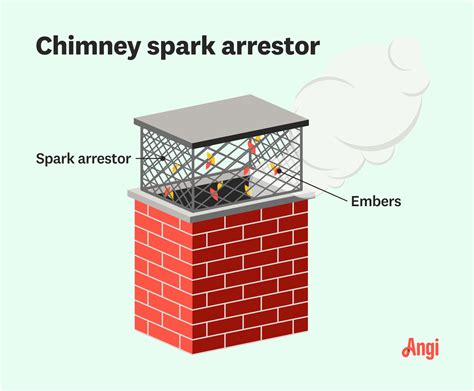

Can spark arrestors be used in residential fireplaces or chimneys?

+

Yes, spark arrestors can be installed in residential fireplaces and chimneys to prevent the escape of sparks and embers. This is especially important in areas with high fire risks or where wood-burning is a common practice.

How often should spark arrestors be cleaned or replaced?

+

The frequency of cleaning or replacement depends on the usage and environment. It is recommended to inspect spark arrestors regularly and clean or replace them as per the manufacturer’s guidelines. In high-risk or dusty environments, more frequent maintenance may be required.